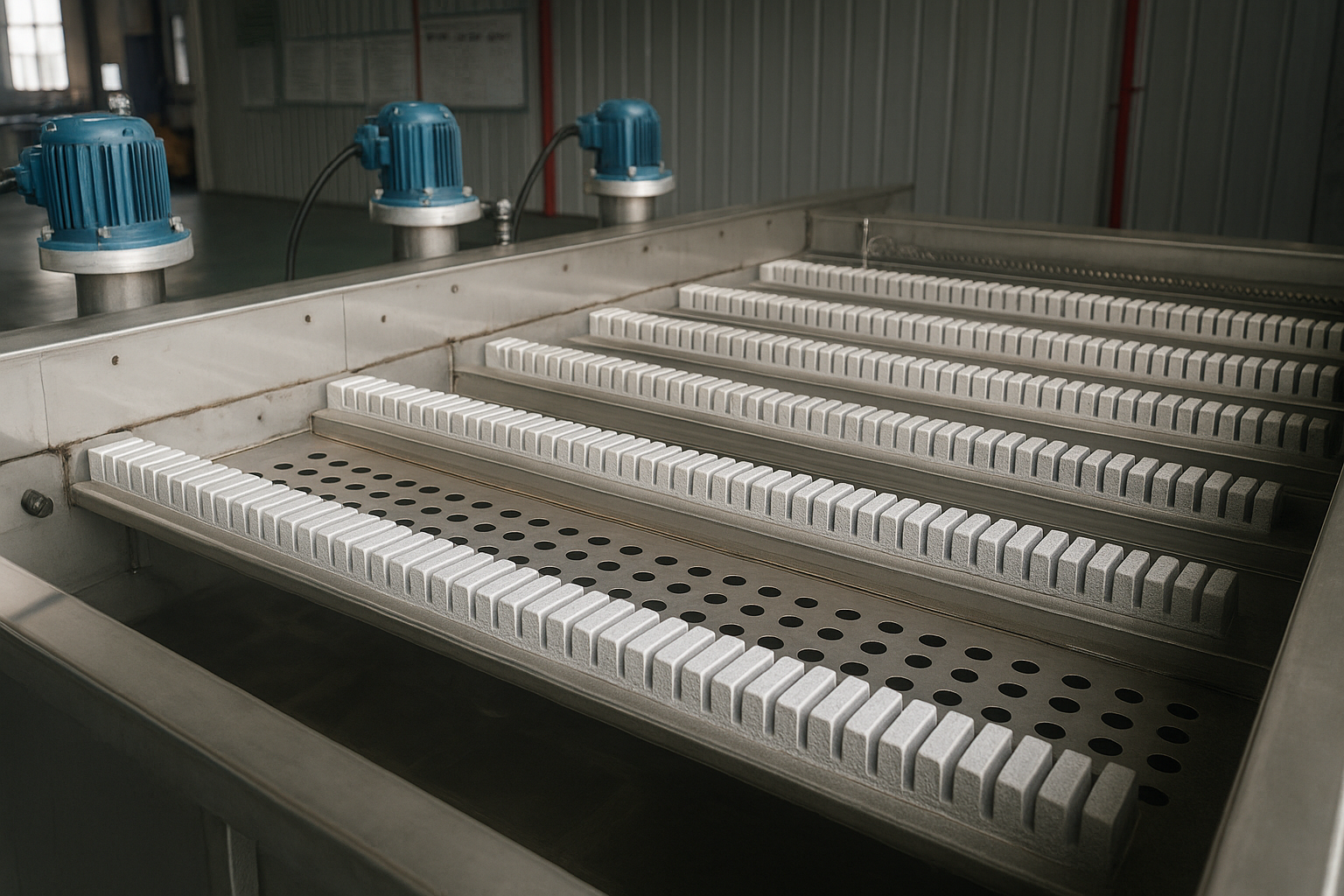

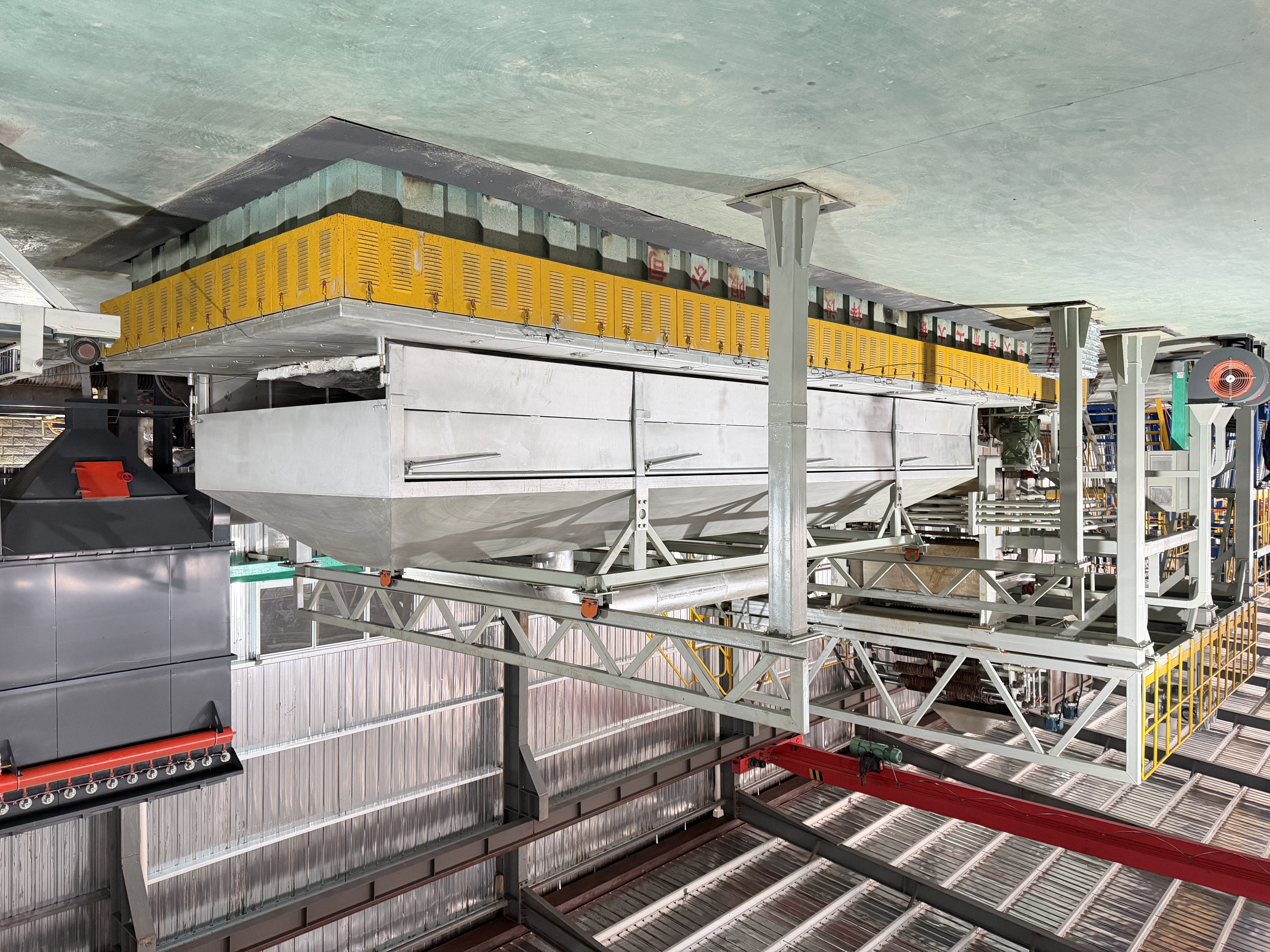

Production Line

At the forefront of China’s hot-dip galvanized steel wire manufacturing, this advanced production line is specifically engineered for wire-based products used in power cables, construction reinforcement, agriculture, and infrastructure. It offers exceptional production efficiency, precise coating control, and consistent mechanical performance. With a focus on durability and eco-friendliness, the entire process—from wire feeding to final packaging—meets high standards of quality assurance and environmental protection.